- Write by:

-

Saturday, December 3, 2022 - 10:20:32

-

385 Visit

-

Print

Mining News Pro - In a paper published in the journal Science, the scientists explain that using only inexpensive raw materials they were able to create a scalable catalyst that needs only the power of light to convert ammonia into clean-burning hydrogen fuel.

According to Mining News Pro - Researchers at Rice University, Syzygy Plasmonics Inc. and Princeton University have engineered a key light-activated nanomaterial for the hydrogen economy.

In a paper published in the journal Science, the scientists explain that using only inexpensive raw materials they were able to create a scalable catalyst that needs only the power of light to convert ammonia into clean-burning hydrogen fuel.

According to the article, liquid ammonia is easy to transport and packs a lot of energy, with one nitrogen and three hydrogen atoms per molecule. The new catalyst breaks those molecules into hydrogen gas and nitrogen gas. Unlike traditional catalysts, it doesn’t require heat. Instead, it harvests energy from light, either sunlight or LEDs.

The paper also explains that the pace of chemical reactions typically increases with temperature, and chemical producers have capitalized on this for more than a century by applying heat on an industrial scale. However, the burning of fossil fuels to raise the temperature of large reaction vessels by hundreds or thousands of degrees results in an enormous carbon footprint. Chemical producers also spend billions of dollars each year on thermocatalysts—materials that don’t react but further speed reactions under intense heating.

Study co-authors Naomi Halas and Peter Nordlander pointed out that the best thermocatalysts are made from platinum and related precious metals like palladium, rhodium and ruthenium. There’s also the possibility of using light-activated (plasmonic) metal nanoparticles to speed up reactions but the best of these are also typically made with precious metals like silver and gold.

Yet, the new work shows that transition metals like iron can become efficient plasmonic photocatalysts when subjected to LED photon sources.

In the researchers’ view, this discovery paves the way for sustainable, low-cost hydrogen that could be produced locally rather than in massive centralized plants.

Antenna-reactors

Following their 2011 discovery of plasmonic particles that give off short-lived, high-energy electrons called “hot carriers,” Halas and Nordlander discovered in 2016 that hot-carrier generators could be married with catalytic particles to produce hybrid “antenna-reactors,” where one part harvested energy from light and the other part used the energy to drive chemical reactions with surgical precision.

The researchers, their students and collaborators have worked for years to find non-precious metal alternatives for both the energy-harvesting and reaction-speeding halves of antenna reactors. The new study is a culmination of that work. In it, Halas, Nordlander, Rice alumnus Hossein Robatjazi, Princeton engineer Emily Carter, and others show that antenna-reactor particles made of copper and iron are highly efficient at converting ammonia. The copper, energy-harvesting piece of the particles captures energy from visible light.

“In the absence of light, the copper-iron catalyst exhibited about 300 times lower reactivity than copper-ruthenium catalysts, which is not surprising given that ruthenium is a better thermocatalyst for this reaction,” said Robatjazi, now chief scientist at Houston-based Syzygy Plasmonics. “Under illumination, the copper-iron showed efficiencies and reactivities that were similar to and comparable with those of copper-ruthenium.”

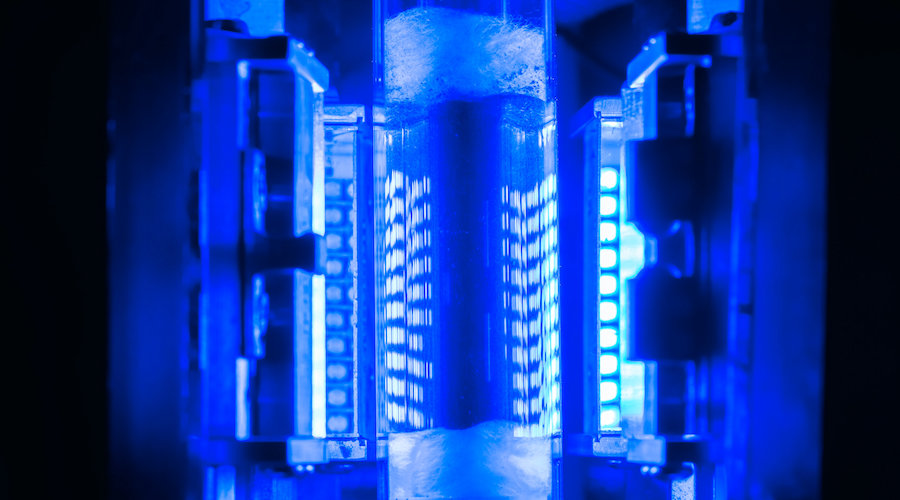

Syzygy has licensed Rice’s antenna-reactor technology, and the study included scaled-up tests of the catalyst in the company’s commercially available, LED-powered reactors. In laboratory tests at Rice, the copper-iron catalysts had been illuminated with lasers. The Syzygy tests showed the catalysts retained their efficiency under LED illumination and at a scale 500 times larger than in the lab setup.

“This is the first report in the scientific literature to show that photocatalysis with LEDs can produce gram-scale quantities of hydrogen gas from ammonia,” Halas said. “This opens the door to entirely replace precious metals in plasmonic photocatalysis.”

The authors believe that given their potential for significantly reducing chemical sector carbon emissions, plasmonic antenna-reactor photocatalysts are worthy of further study.

“These results are a great motivator. They suggest it is likely that other combinations of abundant metals could be used as cost-effective catalysts for a wide range of chemical reactions,” Carter said.

Short Link:

https://www.miningnews.ir/En/News/622409

Zimbabwe’s President Emmerson Mnangagwa has re-appointed Winston Chitando as the southern African nation’s mines ...

Anglo American Plc said it is has received an unsolicited non-binding combination proposal from BHP Group.

Toronto-listed miner OceanaGold Corp said on Wednesday it will raise 6.08 billion pesos ($106 million) through an ...

A key measure of Chinese copper demand just sank to zero, another indication that global prices are not balanced with ...

A new report by IDTechEx states that investing in e-haul trucks could result in major savings for miners due to the ...

Canadian miner First Quantum Minerals (TSX: FM) believes it will be able to take the already mined 121,000 tonnes of ...

Canadian miner First Quantum Minerals said on Tuesday that it has cut its debt by $1.14 billion in the first quarter.

Canada and its Five Eyes Alliance partners are working on put forward a response to tackle the price manipulation of ...

Australia’s Fortescue on Wednesday logged a larger-than-expected decline in third-quarter iron ore shipments, following ...

No comments have been posted yet ...